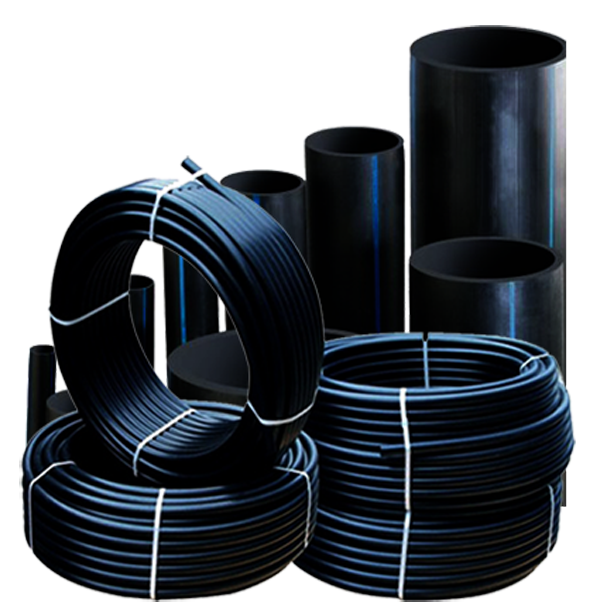

HDPE (High-Density Polyethylene) pipe is a versatile, flexible plastic pipe widely used for the transfer of fluids and gases. It is particularly favored for replacing aging concrete or steel pipelines due to its durability and performance. HDPE is made from high-density polyethylene, which differs from low-density polyethylene (LDPE) primarily in its higher molecular weight, resulting in enhanced strength and rigidity.

Fabrication of HDPE can be achieved through several methods, including the Ziegler-Natta process, the Phillips process, and the gas-phase polymerization method. Each of these techniques affects the material’s properties and suitability for various applications. HDPE is part of the broader polyethylene family, alongside Ultra High Molecular Weight Polyethylene (UHMWPE), which is known for its extreme strength and resistance. UHMWPE is utilized in applications such as bulletproof vests due to its ability to withstand abrasion up to 15 times greater than carbon steel.

Compared to LDPE, HDPE is characterized by its increased hardness, strength, and density, although it is less ductile. Its superior mechanical properties make it ideal for a wide range of applications, including:

Compared to LDPE, HDPE is characterized by its increased hardness, strength, and density, although it is less ductile. Its superior mechanical properties make it ideal for a wide range of applications, including:

- Water mains

- Gas mains

- Sewer systems

- Slurry transfer lines

- Rural irrigation

- Fire system supply lines

- Electrical and communications conduits

- Stormwater and drainage systems

HDPE pipes are valued for their resistance to corrosion, low friction losses, and longevity. They are also easier to install and maintain compared to traditional materials, making them a cost-effective and reliable choice for many infrastructure projects.

FEATURES OF HDPE PIPE:

High-Density Polyethylene (HDPE) pipe is a versatile and widely used material in various industries, from water and gas distribution to industrial applications. Here are some key features of HDPE pipes:

1. Durability and Strength

HDPE pipes are known for their exceptional durability. They have a high impact resistance and can withstand extreme conditions, including temperature fluctuations and pressure variations. Their flexibility allows them to absorb and dissipate stress, which reduces the risk of cracking or breaking.

2. Corrosion Resistance

Unlike metal pipes, HDPE pipes are resistant to corrosion and chemical attacks. This makes them ideal for transporting water, chemicals, and gases in environments where corrosive substances are present.

3. Flexibility

HDPE pipes are highly flexible, which allows them to be bent and installed around obstacles without the need for joints. This flexibility reduces the likelihood of leaks and makes installation easier, especially in complex or uneven terrains.

4. Lightweight

Compared to traditional metal or concrete pipes, HDPE pipes are lightweight, which simplifies handling and transportation. This also reduces the need for heavy machinery during installation, potentially lowering labor and equipment costs.

5. Low Friction Loss

HDPE pipes have a smooth interior surface, which minimizes friction loss and improves the flow of fluids. This can lead to increased efficiency and reduced energy consumption in fluid transport systems.

6. Ease of Installation

The installation process for HDPE pipes is relatively straightforward. They can be connected using various methods such as heat fusion, electro fusion, or mechanical fittings. This adaptability contributes to a faster and more cost-effective installation process.

7. Longevity

HDPE pipes have a long service life, often exceeding 50 years under normal operating conditions. Their resistance to environmental factors and minimal maintenance requirements contribute to their longevity.

8. Environmental Benefits

HDPE pipes are made from recyclable materials, which makes them an environmentally friendly option. Additionally, their durability and longevity contribute to reduced need for frequent replacements, minimizing waste.

9. Pressure Resistance

HDPE pipes can handle high pressure, making them suitable for various applications including potable water distribution, sewer systems, and industrial processes. They are available in different pressure ratings to accommodate specific needs.

10. Temperature Tolerance

HDPE pipes can operate effectively in a range of temperatures, typically from -40°F to 140°F (-40°C to 60°C). Their performance in extreme temperatures is enhanced by their ability to expand and contract without significant loss of structural integrity.

11. Chemical Resistance

HDPE pipes are resistant to a wide range of chemicals, including acids, alkalis, and solvents. This property makes them suitable for transporting a variety of industrial chemicals and wastewater.

12. Non-Toxic

HDPE is a non-toxic material, which makes it safe for transporting potable water and food products. It does not leach harmful substances into the fluids it carries, ensuring safety and compliance with health regulations.

These features make HDPE pipes a popular choice in many applications, from municipal water systems to agricultural irrigation, and they continue to be a preferred material for modern piping solutions.